Unleashing Excellence in Fastener Solutions: The Top Titanium Bolts Manufacturers

In today's fast-paced industrial landscape, the demand for superior fastener solutions has never been more critical. Among the most sought-after materials for high-performance applications is titanium, renowned for its exceptional strength-to-weight ratio, corrosion resistance, and durability. As a leading titanium fasteners manufacturer, titaniumbolts.com stands at the forefront, offering unparalleled quality and innovation in titanium bolts manufacturers industry.

Why Choose Titanium Fasteners? A Game-Changer in Industry

Titanium fasteners have revolutionized multiple sectors, including aerospace, medical, automotive, marine, and industrial machinery. They offer distinct advantages that make them indispensable for demanding environments:

- Exceptional Strength and Lightweight Properties: Titanium's strength closely rivals that of steel but at nearly half the weight, making it ideal for applications where weight reduction is crucial.

- Corrosion Resistance: Titanium's natural oxide layer grants it superior corrosion resistance against chlorides, acids, and seawater, increasing the lifespan of fasteners in aggressive environments.

- High Temperature Resistance: Suitable for applications involving extreme heat, titanium maintains structural integrity where other metals may deform or weaken.

- Biocompatibility: Titanium is biocompatible, making it a preferred material for medical implants and devices.

- Long-Term Cost Efficiency: Despite higher initial costs, titanium fasteners demonstrate excellent durability and minimal maintenance, reducing long-term expenses.

The Role of Leading Titanium Bolts Manufacturers in Industry Advancement

Organizations such as titaniumbolts.com have consistently set industry standards by innovating and refining manufacturing processes to produce the highest quality titanium bolts and fasteners. These manufacturers focus on:

- Material Precision and Quality Control: Sourcing premium-grade titanium and implementing rigorous quality assurance measures ensure every fastener meets strict industry standards.

- Advanced Manufacturing Techniques: Utilizing CNC machining, heat treatment, and surface finishing techniques to produce fasteners with precise dimensions, superior surface quality, and enhanced corrosion resistance.

- Custom Manufacturing Capabilities: Offering bespoke solutions tailored to specific industry needs, including various grades of titanium (Grade 2, Grade 5, Grade 7, etc.) and specialized thread patterns.

- Compliance with International Standards: Ensuring products meet or exceed ASTM, AMS, ISO, and other relevant standards for critical applications.

Comprehensive Range of Titanium Fasteners Offered by Leading Manufacturers

Best titanium bolts manufacturers provide a broad spectrum of fastener solutions, including but not limited to:

Titanium Hex Bolts and Nuts

Designed for heavy-duty applications requiring high strength and reliability. Hex bolts and nuts in titanium eliminate rusting, ensuring long-term performance.

Screws and Socket Head Cap Screws

Ideal for precision machinery and electronics, these fasteners offer exceptional corrosion resistance and precision threading.

Studs and Threaded Rods

Specially manufactured for connecting components in aerospace and industrial applications, offering consistent tensile strength.

Specialty Fasteners

- Eye Bolts and Lifting Rings

- Clamps and Clips

- Fastener Assemblies with Customized Coatings

The Industry Applications of Titanium Fasteners and Their Impact

From high-altitude aerospace components to cutting-edge medical devices, titanium bolts manufacturers supply essential components that influence several sectors:

Aerospace and Defense

Weight reduction and durability are paramount. Titanium fasteners reduce overall aircraft weight, enhancing fuel efficiency, while resisting corrosion in harsh environments.

Medical Industry

Biocompatible titanium fasteners are fundamental for implants, dental devices, and surgical instruments, ensuring safety and longevity.

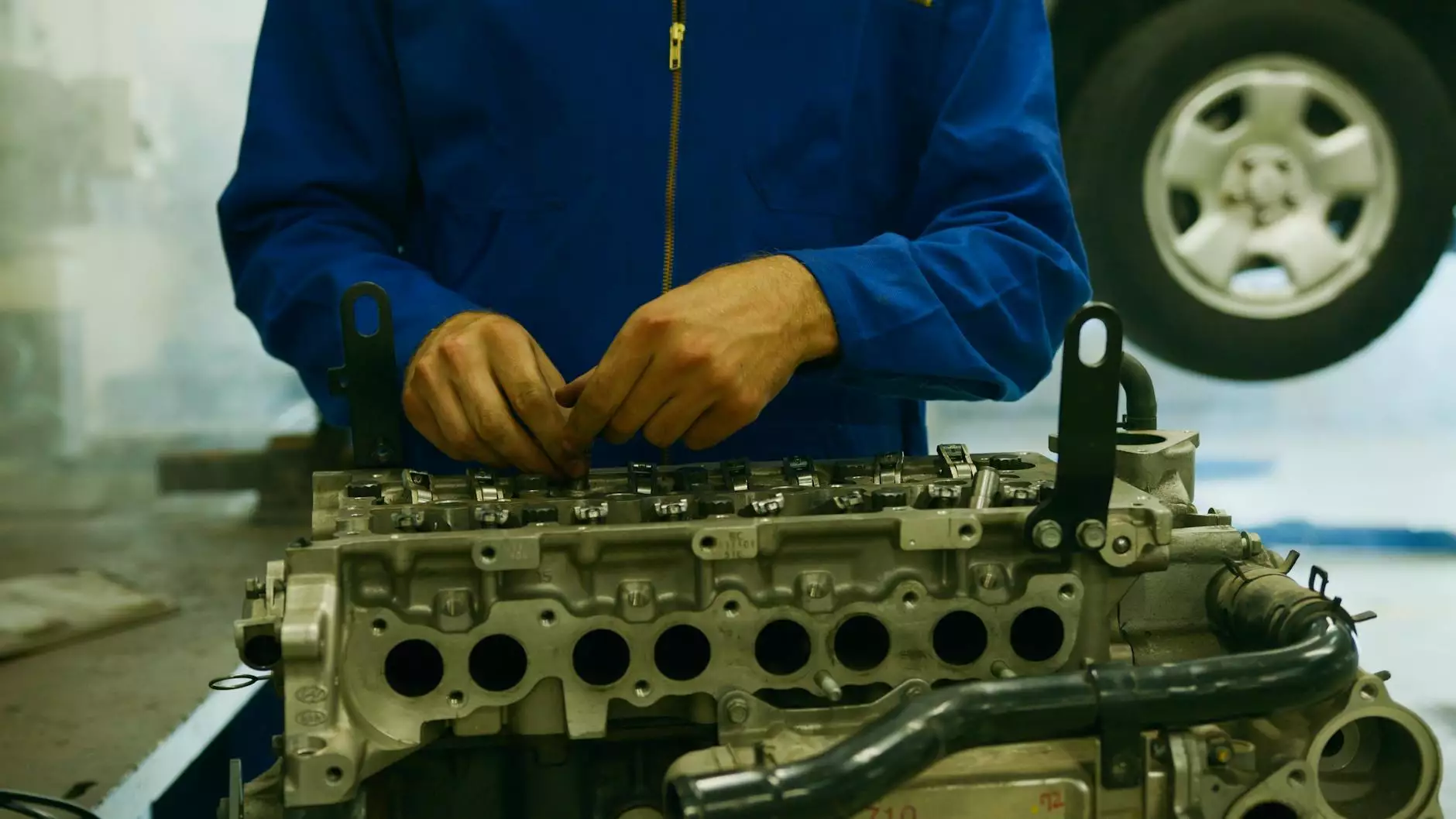

Automotive

High-performance vehicles benefit from lighter, stronger fasteners capable of enduring high stress and temperature ranges, leading to enhanced speed and safety.

Marine and Offshore

Resistant to seawater corrosion, titanium fasteners are essential for ships, submarines, and offshore platforms, ensuring durability in aggressive marine environments.

Why Partner with Top Titanium Bolts Manufacturers? Advantages You Can't Overlook

- Superior Product Quality: Premium raw materials and meticulous manufacturing processes guarantee reliable, long-lasting fasteners.

- Customization: Ability to produce tailored solutions to meet unique project requirements.

- Technical Expertise: Skilled engineers and quality assurance teams ensure optimal performance and adherence to standards.

- Timely Delivery: Efficient logistics and supply chain management minimize project delays.

- Competitive Pricing: Cost-effective solutions without compromising on quality.

How to Choose the Best Titanium Bolts Manufacturers?

Ensuring your organization partners with the right titanium bolts manufacturers involves considering several key factors:

- Experience and Industry Reputation: Select manufacturers with proven track records in producing high-quality titanium fasteners.

- Certifications and Standards: Verify adherence to industry certifications such as ISO 9001, ASTM, and AMS standards.

- Material Sourcing: Ensure the use of high-grade titanium materials, such as Grade 5 or Grade 2.

- Product Range and Customization: The ability to supply diverse fastener types and customize solutions as per project specifications.

- Customer Support and After-Sales Service: Responsive service, technical support, and warranty policies are vital for long-term partnership.

The Future of Titanium Bolts Manufacturing: Innovations and Trends

As industries evolve, so do the manufacturing techniques and applications of titanium fasteners:

- Advanced Coatings: Development of anti-galling and lubricious coatings to enhance performance.

- 3D Printing: Additive manufacturing techniques facilitate complex designs and rapid prototyping.

- Smart Fasteners: Integration of sensors for structural health monitoring and maintenance.

- Sustainable Manufacturing: Focus on reducing environmental impact through eco-friendly processes.

Conclusion: Embrace Quality and Reliability with Top Titanium Bolts Manufacturers

Choosing the right manufacturer for titanium bolts and fasteners is paramount to ensuring safety, performance, and long-term value across various high-stakes industries. titaniumbolts.com exemplifies excellence, combining advanced manufacturing, rigorous quality control, and comprehensive customization options to meet the dynamic needs of clients worldwide.

With the increasing demand for lightweight, corrosion-resistant, and high-strength fasteners, partnering with elite titanium bolts manufacturers guarantees your projects are equipped with the most reliable and innovative solutions available today.

Invest in Quality, Choose Titanium Fasteners for the Future

In conclusion, titanium fasteners are a strategic investment for industries seeking durability, efficiency, and resilience. Leading titanium bolts manufacturers continue to push the boundaries of technology, ensuring your applications maintain peak performance under the most challenging conditions. Reach out to trusted industry leaders and secure high-quality titanium fasteners that stand the test of time.